OPC UA Server, a cornerstone of modern industrial automation, provides a standardized platform for data exchange and communication between diverse devices and systems. It empowers seamless interoperability, facilitating the integration of disparate technologies within complex industrial environments.

This technology bridges the gap between legacy systems and cutting-edge technologies, enabling real-time data access, advanced analytics, and enhanced control over industrial processes. Its robust security features and flexible data modeling capabilities ensure reliable and secure operations, making it an indispensable tool for optimizing industrial efficiency and productivity.

Introduction to OPC UA Server

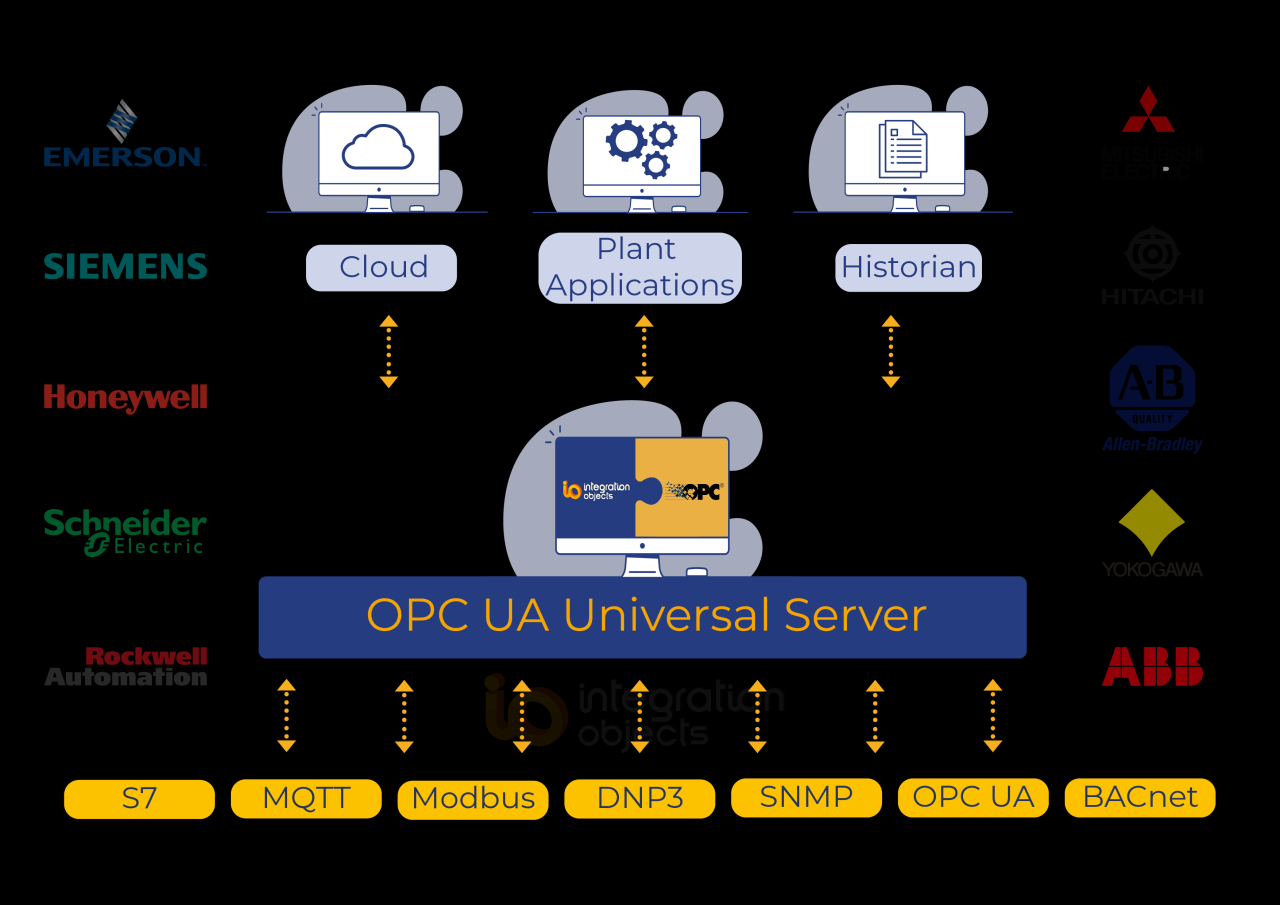

An OPC UA Server acts as a central hub for industrial data, providing a standardized way to access and exchange information between different devices and systems within a manufacturing environment. It enables seamless communication and interoperability between various automation components, regardless of their underlying protocols or technologies.

The primary purpose of an OPC UA Server is to facilitate data exchange and integration in industrial automation systems. It acts as a bridge between different devices, enabling them to communicate and share data efficiently.

Benefits of Using OPC UA Server

OPC UA Servers offer numerous advantages in industrial environments, contributing to enhanced efficiency, productivity, and overall system performance.

- Improved Interoperability: OPC UA provides a common language for communication, allowing devices from different manufacturers to seamlessly interact, regardless of their underlying protocols. This eliminates the need for custom integrations and reduces compatibility issues.

- Enhanced Security: OPC UA incorporates robust security features, including authentication, authorization, and encryption, ensuring data integrity and protecting against unauthorized access. This is crucial for safeguarding sensitive industrial data and maintaining system reliability.

- Increased Data Availability: OPC UA Servers provide real-time access to data from various sources, enabling applications to monitor and control processes more effectively. This real-time data visibility enhances decision-making and optimizes operational efficiency.

- Simplified System Integration: OPC UA simplifies the integration of new devices and systems, reducing the time and effort required for setup and configuration. This allows for faster deployment of new technologies and improved system scalability.

- Reduced Maintenance Costs: The standardized communication protocol of OPC UA reduces the need for specialized hardware and software, leading to lower maintenance costs and simplified system management.

Applications of OPC UA Server

OPC UA Servers are widely used across various industries and applications, playing a crucial role in modern industrial automation.

- Manufacturing: OPC UA Servers enable real-time monitoring and control of manufacturing processes, including machine operation, production line management, and quality control. They facilitate data collection, analysis, and optimization, leading to improved efficiency and reduced downtime.

- Energy: In the energy sector, OPC UA Servers are used for managing power generation, distribution, and consumption. They enable remote monitoring and control of power plants, wind turbines, and other energy infrastructure, optimizing energy efficiency and grid stability.

- Process Automation: OPC UA Servers are essential for process automation in industries like chemicals, pharmaceuticals, and food processing. They provide real-time data access for process control, optimization, and safety monitoring, ensuring efficient and reliable operations.

- Building Automation: OPC UA is increasingly used in building automation systems for managing HVAC, lighting, security, and energy consumption. It enables centralized control and monitoring, improving energy efficiency, comfort, and safety.

Last Recap

In conclusion, OPC UA Server stands as a pivotal force in the evolution of industrial automation. Its ability to connect, control, and optimize industrial processes has transformed the landscape, paving the way for a future where interconnected systems and intelligent decision-making drive unprecedented levels of efficiency and innovation. As industries continue to embrace the power of data and automation, OPC UA Server will undoubtedly play a vital role in shaping the future of industrial operations.

OPC UA servers are essential for real-time data exchange in industrial automation, offering a standardized way to access and control equipment. But sometimes, a break from the digital world is needed, and a creative outlet like crafting your own diy clothes can be a refreshing change of pace.

After all, just like OPC UA servers provide a structured framework for industrial data, a well-designed DIY project can offer a sense of order and accomplishment. And when you’re ready to return to the world of automation, the insights gained from a creative endeavor can often be applied to solving complex technical problems.